Blue Orange Wave: Out-of-the-box-thinking during global COVID-19 pandemic

Blue Orange Wave: Out-of-the-box-thinking during global COVID-19 pandemic.

June 3, 2020. The entire world seemed to have stopped turning due to the global COVID-19 pandemic. What historically should have been a great period in our field of business stopped from one day to another! The first reports arrived of massive infections, daily counts of mortal victims, intelligent lockdown on SMEs and governmental orders to work from home. The only growth reported was the capacity of ICUs and Corona divisions in the national hospitals. With this enormous wave of infections there was an enormous high demand on personal protective equipment (PPE) for healthcare professionals globally which colored the horizon for safe and certified deliveries to the Dutch national hospitals dark grey to totally black.

PPE Shortage

Especially this last part, the shortage of PPE and therefore the great number of infections among these first line healthcare workers, was what made Tim Lodder, founder and CEO of Blue Orange Wave, and Marc Derks, sr. project manager at Damen Shipyards Group, creative in looking for an out-of-the-box solution for this challenge to be found in the industrial and consumer markets. The start was made with what now, 10 weeks after, is the Air-Wave.org Protector™.

Together with colleagues from the maritime industry, Lodder managed to mobilize his professional networks to deploy knowledge and expertise in workplace safety, healthcare regulatory and product development capabilities. The continious growing team of experts started brainstorming on a solution that had to be comfortable, sustainable, (fail) safe and national-of-the-shelf, since there was no time to waste!

Private-Public Collaboration

They decided to connect a PAPR (Powered Air Purifying Respirator) with P3 filter set, used in the welding and maritime industry, to a widely available snorkelmask using a 3D-printed coupling to create a positive pressure mask with filtered air. From the first prototype with a coupling created from a piece of bicycle tire it took the team of 40 devoted volunteers six days to deliver a market ready product covering all set requirements. Finally, the project united in the not-for-profit Air-Wave.org Foundation facilitated by a total of 35 companies in maritme and healthcare, consumer products to supply chain and logistics from the national Dutch industries, tech-universities and a group of medical specialists and experts.

The Air-Wave.org Protector

The product was ready within six days, the national Dutch coordination center for supply of equipment to the Dutch national hospitals was not due to their daily challenges. The Air-Wave.org team continued in several areas with their lobby and improvements. They continued improving the market ready solution to raise the standard. Testing procedures were developed to expand with full shift comfort tests which gave a better inside to usability and more important durability. There was time to innovate and improve!

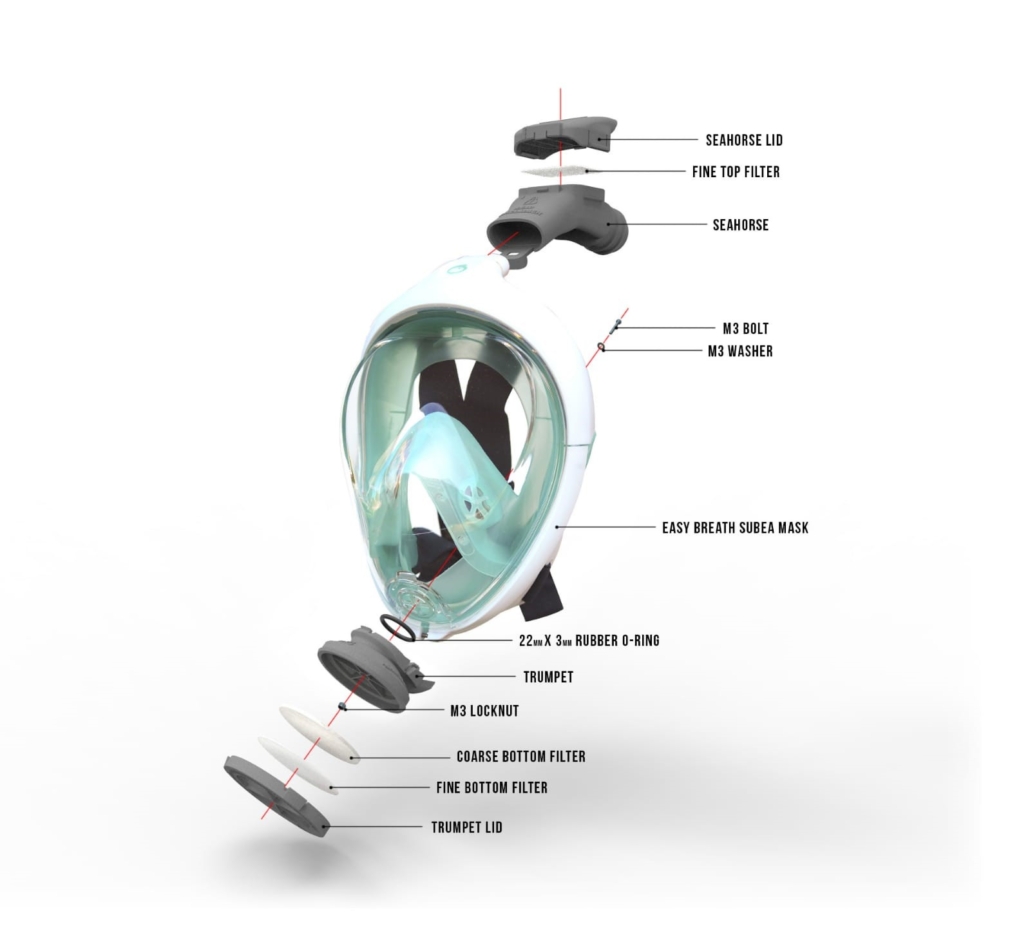

Finally afer three weeks of testing with a clear focus on safety for the healthcare professional, bystander and patient, the comfort and durability increase immensely. The team registered and patented a set of 3D-printed connector pieces which will be added to the standard snorkelmask without damaging the existing mask. The most innovative improvement is located in the Seahorse, the connection piece between the snorkelmask and tube from the PAPR. This connection piece now includes a pressure valve based on filter resistance to control the positive pressure in the mask and provides a comfortable but safe use. The Trumpet, the 3D-printed connection piece on the chin of the mask, includes an expansion filter to lower the sound caused by the outflowing air and the filter protects bystanders and patients. Fact is that all in- and outgoing airflows will be filtered based on a P2+ filter efficiency .

CE Marking and future development

Currently the Air-Wave.org Protector is used by healthcare professionals in several hospitals in the Netherlands and by individuals from Belgium and the USA. Luckily, now the crisis situation has died down, we as a society have to be very vigilent about future developments on infections globally and eventually be prepared for a possible second wave. Current days with less receiving requests from other hospitals in the Netherlands and abroad the team is still very energized to help and prepare for the future. Several track are moving forward; The Ministry of Healthcare is involved as well as the Notified Body to certify this solution for the European CE marking and make it widely available within Europe. On another track the team prepares the Air-Wave.org Protector to be available globally by connecting networks of 3D printing capacity, supply chain and logistics.

Test results, dressing and cleaning protocols, assembly details and order forms can be found on the Foundation’s website https://www.air-wave.org. The Air-Wave.org Protector is ready for global use as Tim mentioned.

We at Blue Orange Wave are very proud to demostrate that with a common goal and full dedication of a great team, you really can make a difference with little out-of-the-box thinking.

Our team will always do the utmost to deliver the best solutions possible and go beyond for safety and sustainability to enhance the quality of maritime training.